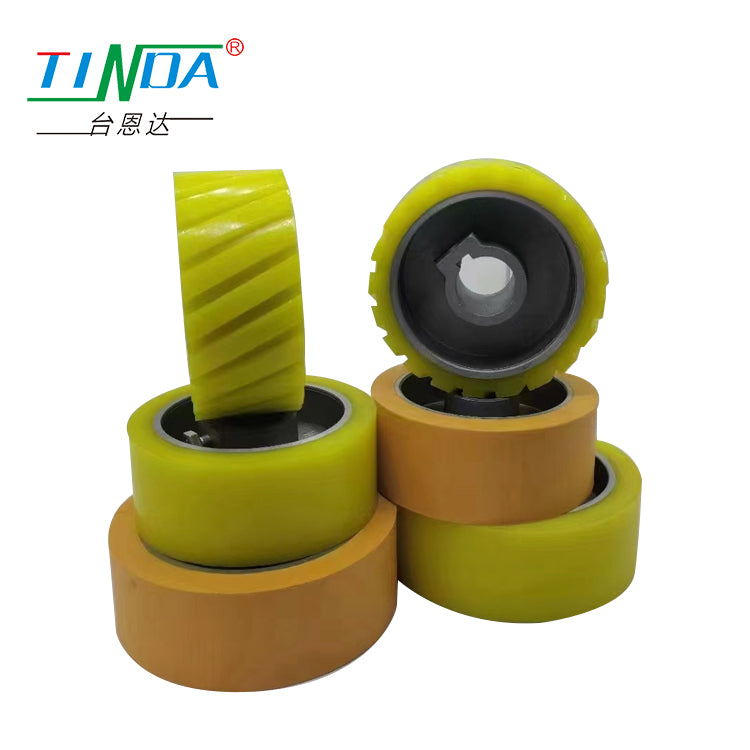

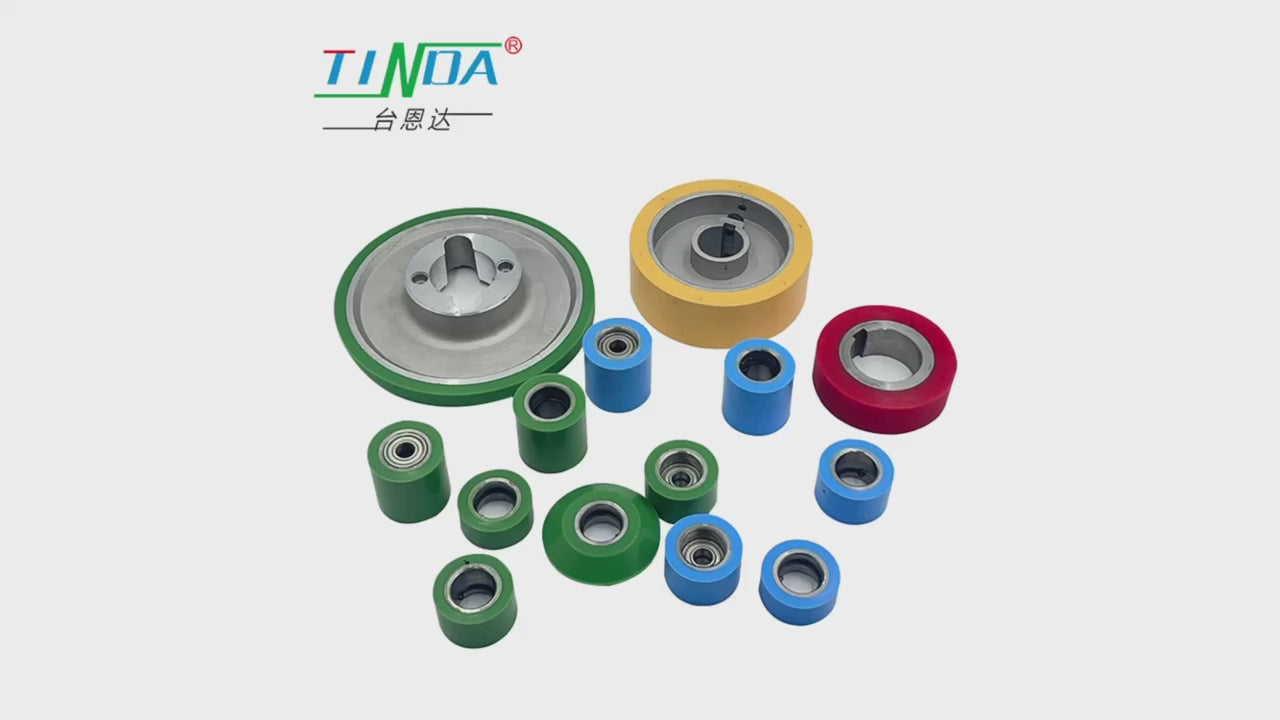

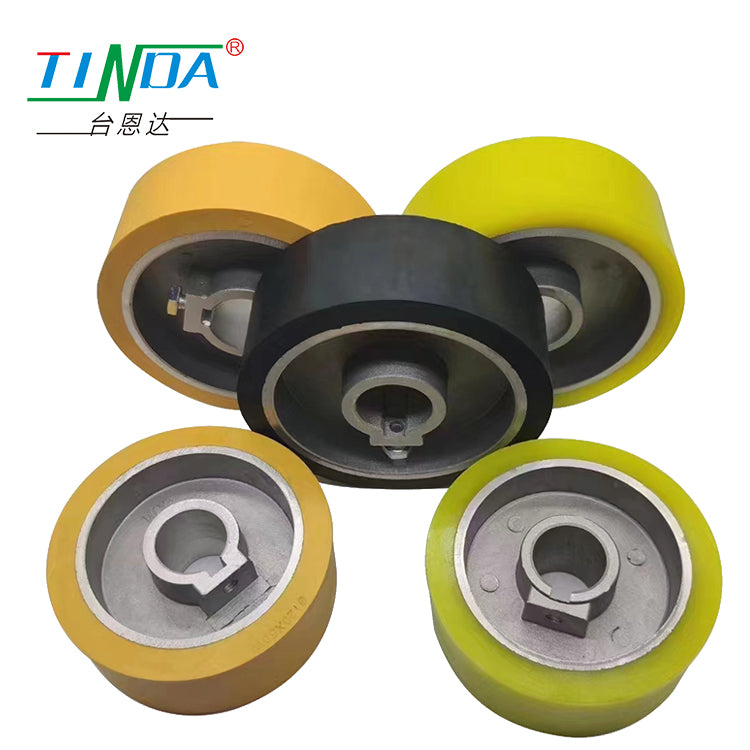

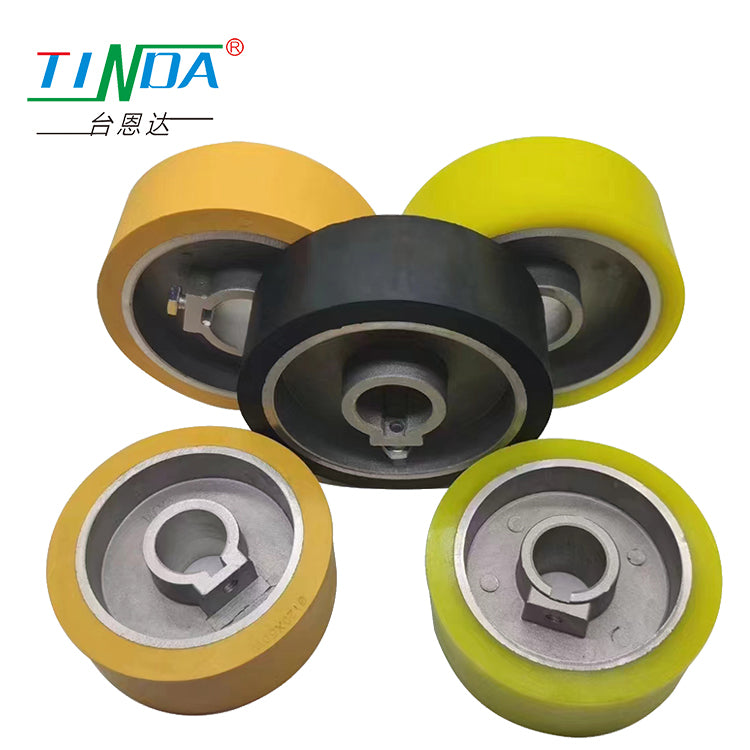

Woodworking machinery rubber wheel

Features:

Woodworking machinery rubber wheel is a kind of accessories for woodworking machinery processing, usually made of rubber, plastic, metal and other materials. Its main role is to fix the wood to the machinery for processing through the friction force with the wood surface.

√Rubber wheels for woodworking machinery are usually made of high strength materials, such as fiberglass or ceramics.

√The surface of the rubber wheel of woodworking machinery has rough sand grains, which can effectively grind the wood surface and improve the cutting efficiency and accuracy.

| Pressure wheel | Specificatiol | Pressure wheel | Specificatiol | Pressure wheel | Specificatiol |

|---|---|---|---|---|---|

| 01 | Φ50X60 | 11 | Φ60X20X5 | 21 | Φ60X30XR1 |

| 02 | Φ50X50 | 12 | Φ60X20XR3 | 22 | Φ60X20 |

| 03 | Φ50X40 | 13 | Φ60X20XR5 | 23 | Φ60X30X20 |

| 04 | Φ50X30 | 14 | Φ60X20XR8 | 24 | Φ60X30 |

| 05 | Φ50X20 | 15 | Φ60X30XR10 | 25 | Φ120X20 |

| 06 | Φ50X10 | 16 | Φ60X30XR11 | 26 | Φ120X20 |

| 07 | Φ60X20XR1 | 17 | Φ60X30XR29 | 27 | Φ120X20XR1 |

| 08 | Φ50X60XR1.5 | 18 | Φ65X20XR1 | 28 | Φ120X20X15 |

| 09 | Φ50X60XR1B | 19 | Φ60X30XR5 | 29 | Φ120X20X10 |

| 10 | Φ60X20X10 | 20 | Φ60X30XR3 | 30 | Φ80X20 |

| Pressure wheel | Specificatiol | Pressure wheel | Specificatiol | Pressure wheel | Specificatiol |

|---|---|---|---|---|---|

| 31 | Φ80X20X5 | 41 | Φ60X20X5(Nylon) | 51 | Φ70X30X5(Aluminum) |

| 32 | Φ80X20X10 | 42 | Φ60X20X2(Nylon) | 52 | Φ70X30XR1(Aluminum) |

| 33 | Φ80X20XR1 | 43 | 60X20X2(Right Angle nylon) | 53 | 0X30XR1(Aluminum) |

| 34 | Φ80X10 | 44 | Φ80X20XR1(Nylon) | 54 | 60X30XR15(Aluminum) |

| 35 | Φ60X20X3(Si) | 45 | Φ60X20XR1(Nylon) | 55 | Φ50X30(Concave) |

| 36 | Φ60X20X2(Si) | 46 | Φ60X20XR2(Aluminum) | 56 | Φ50X20(Concave) |

| 37 | Φ50X30(45°) | 47 | Φ60X20XR1(Aluminum) | 57 | Φ70X30(Concave) |

| 38 | Φ60X20XR1.5(Nylon) | 48 | Φ60X20X3(Aluminum) | 58 | Φ60X20XR5(Concave) |

| 39 | Φ60X20XR1B(Nylon) | 49 | 60X20XR1B(Aluminum) | 59 | Φ60X20XR5(Concave) |

| 40 | Φ60X20X3(Nylon) | 50 | Φ60X20X5(Aluminum) | 60 | Φ35X23 |

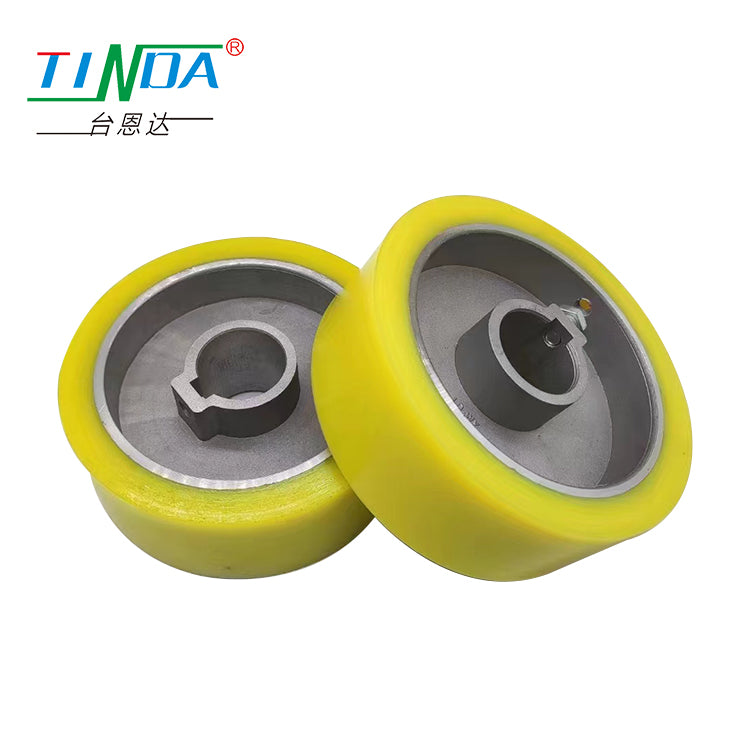

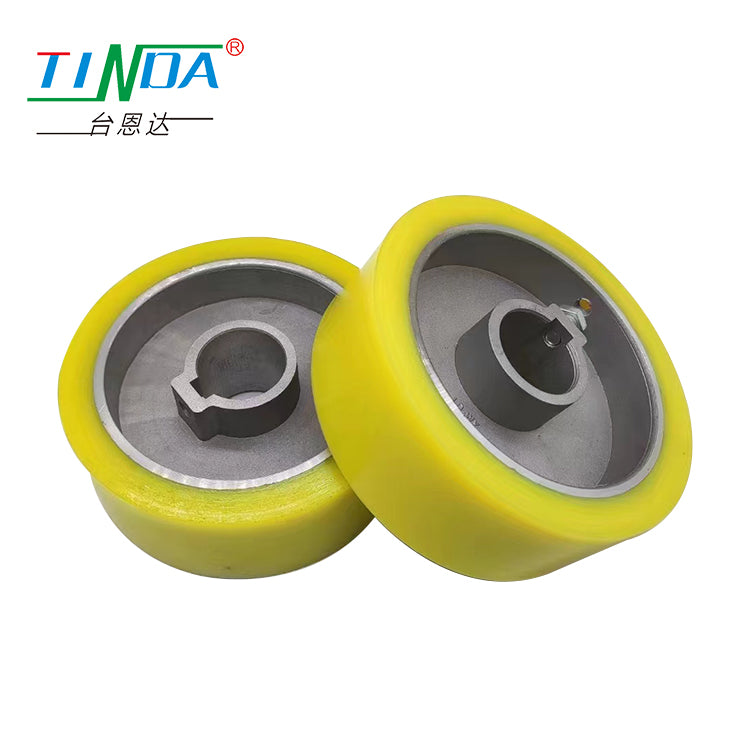

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

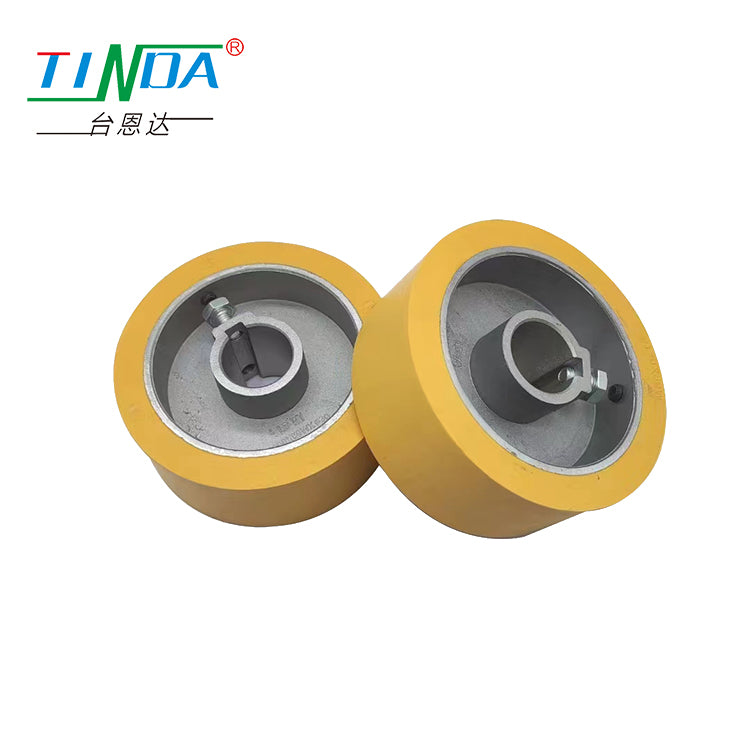

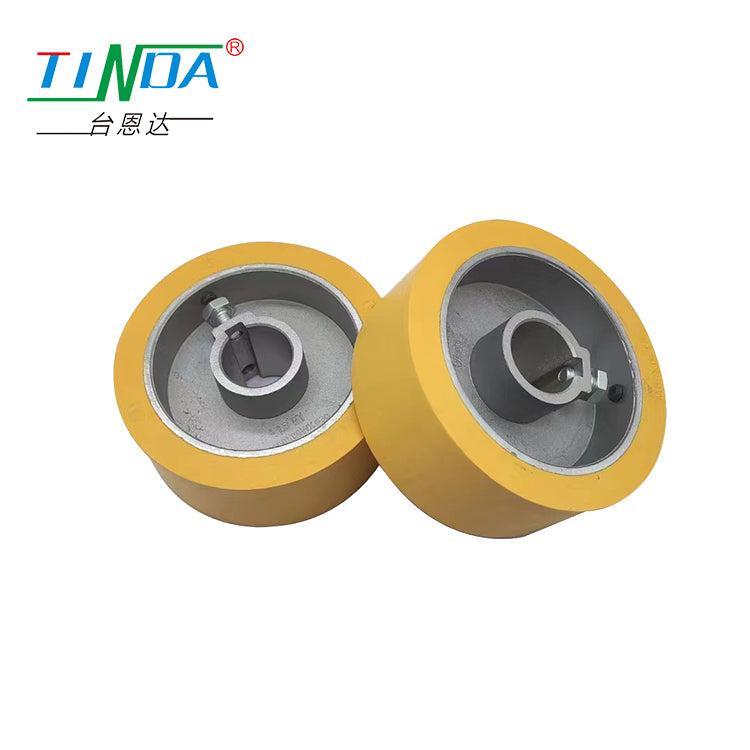

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements