Excellent flame retardant. Goodelectrical insulation performance.Good flexibility, high compression rate

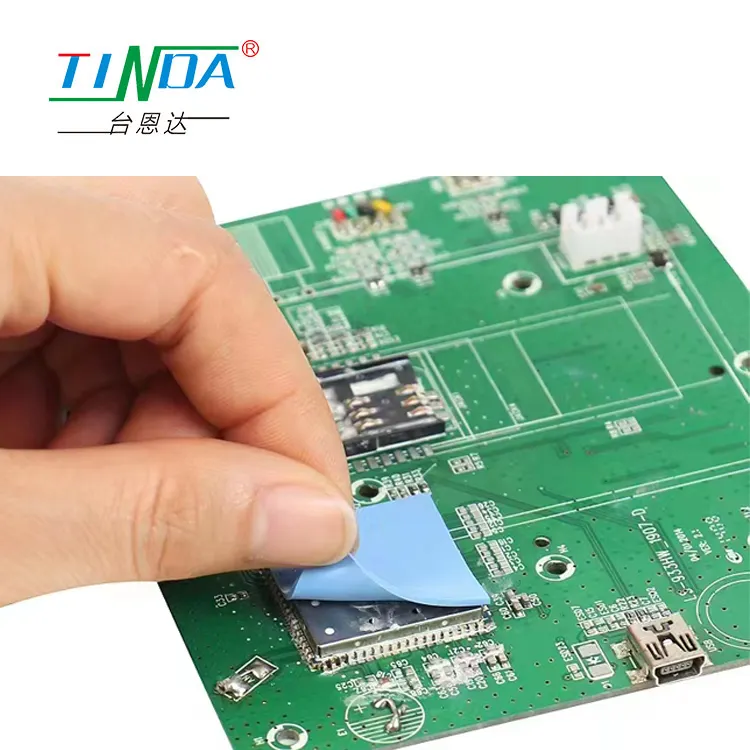

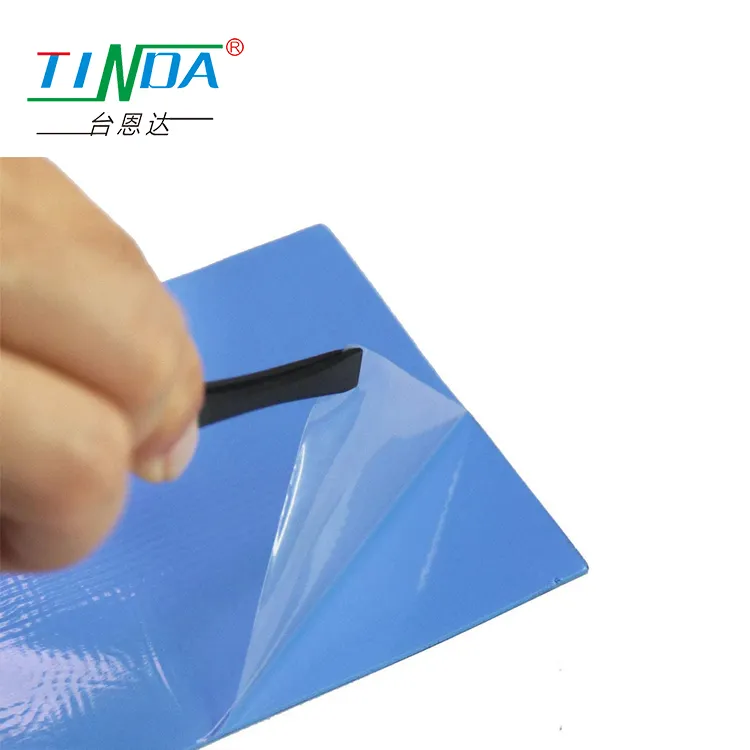

Surface fit

Good flexibility high compression rate

Excellent flame retardant

Good electrical insulation

| type | Color | Qi electric breakdownPressure (VAC) |

Thermal limit@50psi (C-inW) |

The volume resistance (ohm-cm) |

|---|---|---|---|---|

| Tinda500 | Brown | >6000 | 0.45 | 1022 |

| Tinda5000 | Double Claro | >6000 | 0.35 | 1022 |

| Tinda100 | Whtie | >6000 | -- | 1022 |

| Tinda300 | Yellow | >6000 | 0.53 | 1022 |

| Tinda400 | Gray | >5500 | 0.63 | 1022 |

| Tinda3000 | Gray | >6000 | 0.55 | 1022 |

| TindaK52-1 | Light amber | 4200 | 0.13 | 4x1014 |

| TindaK52-2 | Light amber | 7800 | 0.22 | 4x1014 |

| TindaK52-3 | Light amber | 9000 | 0.31 | 4x1014 |

It has sealing and water vapor sealing ability. It has good electromagnetic shielding, and can provide good conductivity under certain pressure. lt has high and low temperature resistance and electrolytic corrosion resistance

| Test standard | Unit | 8520 | 8700 | 8710 | 8800 | 8812 | 8813 | 8817 | ||

|---|---|---|---|---|---|---|---|---|---|---|

| base material | --- | --- | si | si | si | si | si | si | si | |

| Conductive filling material | --- | --- | --- | Ag/Cu | Ag/A1 | Ag/Ni | Ni/C | Ni/C | Ni/C | |

| Volume resistivity | MIL-DTL-83528C | mOhm | --- | 2 | 8 | 15 | 8 | 8 | 12 | |

| cm | ||||||||||

| Density | No curing | --- | g/cm³ | 0.9 | 2.5 | 1.7 | 2/6 | 2 | 1.9 | 1.6 |

| After curing | ISO 2781 | 1.1 | 2.9 | 1.9 | 3.1 | 2.2 | 2.1 | 1.9 | ||

| Hardness | ISO 7619 | shore | 40 | 55 | 65 | 55 | 80 | 73 | 63 | |

| A | ||||||||||

| Tensile strength | ISO 37 | Mpa | 5.6 | 2.1 | 2 | 2.9 | 2.8 | 2.5 | 2.6 | |

| Largest elongation | ISO 37 | % | 570 | 310 | 140 | 240 | 100 | 170 | 260 | |

| Tear strength | ISO 34-1C | N/mm | 24 | 12 | 14 | 14 | 13 | 15 | 16 | |

| The matAfter moldingEffect of shieldingcan |

0.3-9Ghz | Nolatocavity to cavity testmethod | dB | --- | --- | 70 | 107 | --- | --- | --- |

| 0.3-20Ghz | 75 | --- | --- | 130 | 130 | 110 | ||||