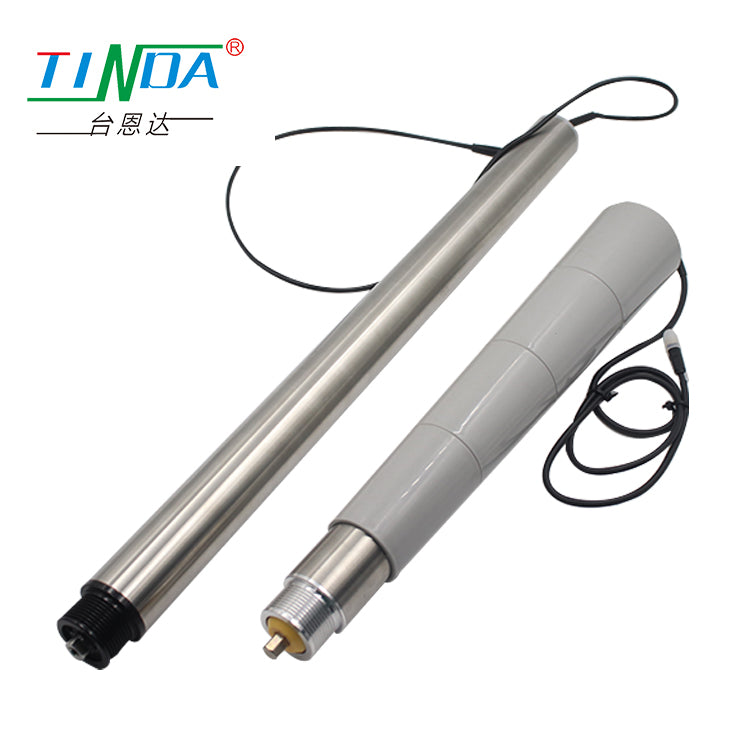

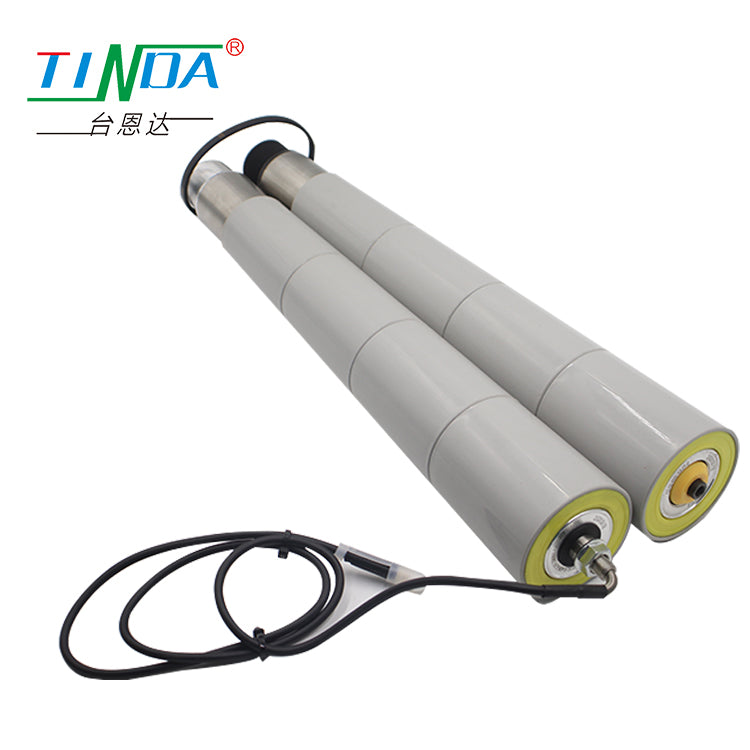

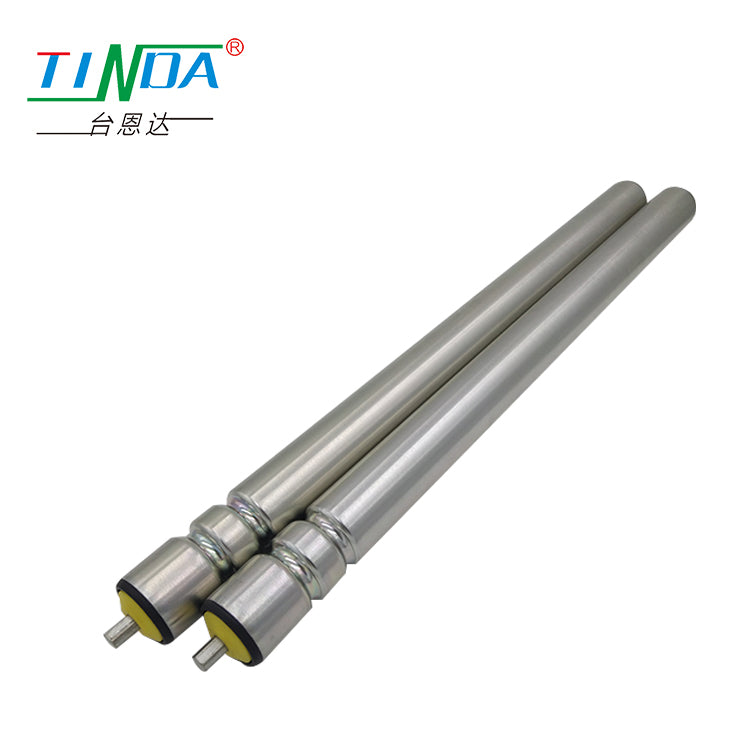

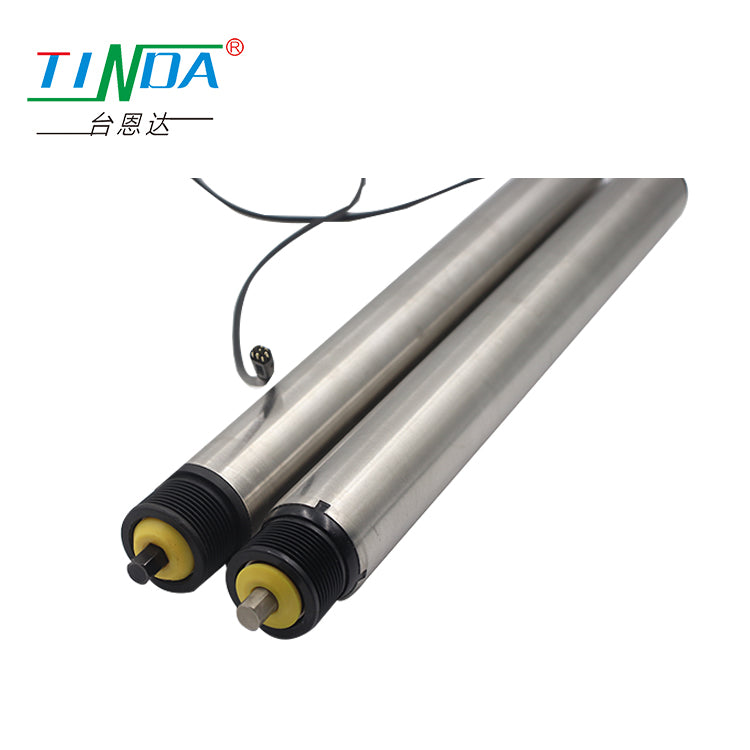

POWERED DRIVEN ROLLERS

Features:

Powered driven rollers is an efficient DC drive for unit load handling systems, e.g. for transporting cartons, trays, workpiece carriers or tyres at normal ambient temperatures. Suitable for straight conveyors, small belt conveyors. It can also be used in shuttle systems, aligning conveyor segments or transfers or other "conveyor system branches".

| ECO mode | BOOST mode | |

|---|---|---|

| LOAD PLATFORM(TRANSFER OF WEIGHT) | <30kg | <50kg |

| LSPEED CODE | 15M | |

| LRATED TORQUE | 2.97N▪M | 5.4N▪M |

| LSPEED RANGE | 2.0~20.3m/min | 2.0~14.7m/min |

| LHIGHEST EFICIENCY | 2400 pieces/hour | |

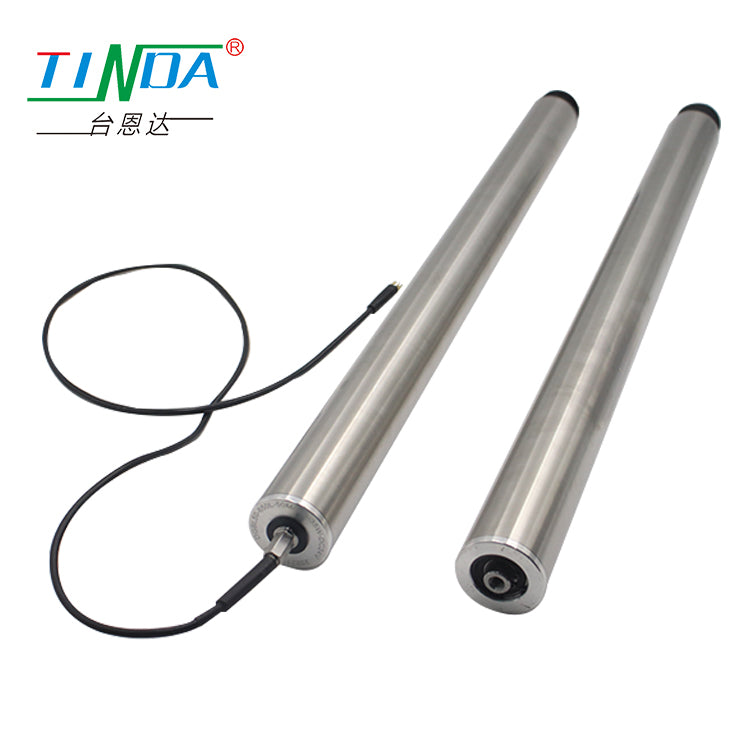

NON-POWERED RPLLERS

Features:

Non-powered rollers is a conveyor used in an automated final assembly line. The mechanical part is mainly composed of a frame, a drum and a guide and a guard. According to product process requirements, manual push transfer to complete the required function.

| plpe diameter | Wall thickness | trummion | Simplified form material |

|---|---|---|---|

| PVC | |||

| Φ20 | 1.1 | Φ6 | √ |

| Φ25 | 1.8 | Φ8 | √ |

| Φ30 | 1.8 | Φ8 | √ |

| Φ38 | 2.0 | Φ8/Φ10 | √ |

| Φ50 | 2.5 | Φ8/Φ10/12 | √ |

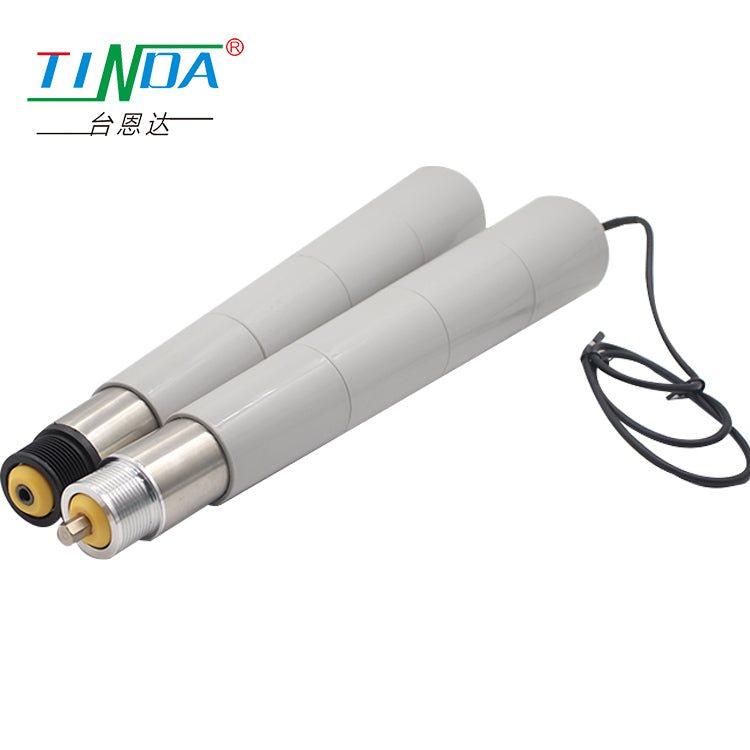

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements