Can be used in various printing machinery, industries:packaging printing, textile printing, plastic printing,etc.

Uv roller special

Strong corrosion resistance

Corrosion resistance,UV ink, UV ink drying has no adverse effects, and the ink affinity of contact can ensure excellent printing quality without surface slipping. Does not affect the ink viscosity to ensure long-term stable ink supply

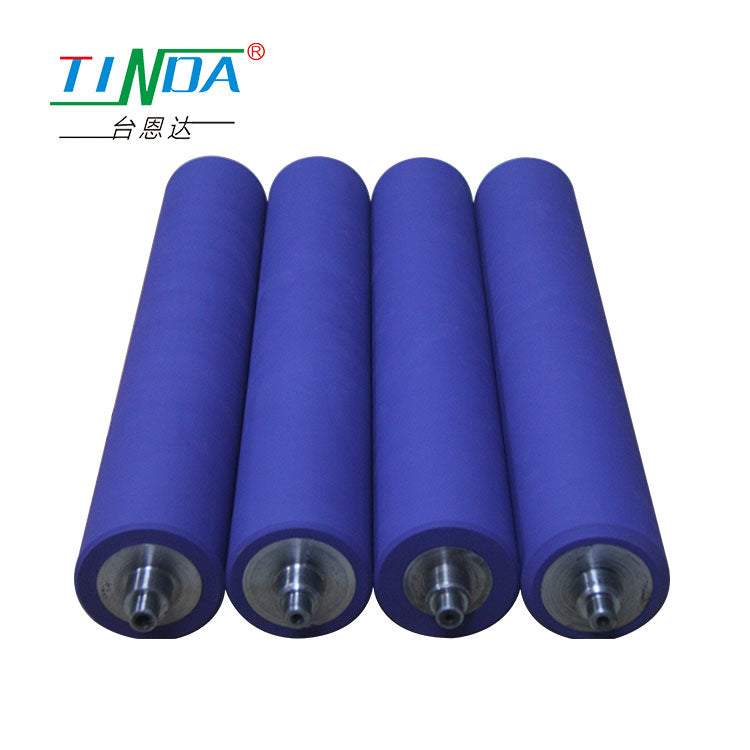

Lnk roller

Good oil resistance, low heat generation,easy to clean

Imported material, which can replace the origina lmechanical ink roller, has excellent oil resistance,low heat generation, easy cleaning, good surface performance, and good absorption and transfer of ink.

Alcohol water roll

Good flexibility, good hydrophilicity

lmported material, which can replace the original mechanical ink roller, has excellent oil resistance,low heat generation, easy cleaning,good surfa ceperformance, and good absorption and transfer of ink.

Uv dual purpose rubber roller

Strong applicability and more popular

It can solve the problem that the same machine needs to replace the rubber roller frequently due to ink change, so it is generally welcomed. The uv ordinary dual-purpose rubber roller is suitablefor both uv ink and ordinary ink.

Metering roller

Mirror roller has the advantages of high unit strength, light weight, small inertia, bright surface and no rust, etc. It is widely used in gravure printing, coating, coating, film blowing,laminating, coating, cutting, papermaking, textile and other production lines.

Ceramic Anilox roller

Flexographic printing machines use a typical short ink supply system, in which the anilox roller is the core component of flexographic printing machines, it is responsible for the uniform transfer of a certain amount of ink to the plate.

Ultrasonic cleaners

Good cleaning effect, fast cleaning speed, improve production efficiency, no manual conact with cleaning fluid, safe and reliable. It can also clean deep holes, fine cracks and hidden parts of the workpiece, and there is no damage to the surface of the workpiece

Multiple specifications Multiple options

Can choose the applicable design with the actual situation, can pressCustomer requirements processing customized

| Papermaking roller | Printing and dyeing roller | Printing roller | |||

|---|---|---|---|---|---|

| Name | Hardness | Name | Hardness | Name | Hardness |

| Press roller | 80°-90° | Press roller | 92°-97° | High speed rotary press roller | 20°-25° |

| Water extrusion roller | 75°-85° | Mercerized roller | 80°-85° | High-speed platform ink roller | 80°-85° |

| Dryer roller | 85°-95° | Mercerizing flat washroller | 80°-85° | General platform ink rolle | 100° |

| copper mesh roller | 35°80° | Flat Wash upper roller | 100° | Offset press grinding roller | 80° |

| Blanket dispensing roller | 95°-100° | Flat Wash lower roll | 80° | General printing ink roller | 85°-90° |

| Case roller | 95°-100° | Rope washing machine roller | 85°-90° | Strong solvent glazing roller | 85° |

| Breast roller | 70°-80° | Tie dyeing roller | 85° | Strong solvent glazing roller | 60°-70° |

| Wool cloth guide roller | 95°-100° | Hollow bending roller | 60°70° | lron printing roller | 95°-100° |

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements