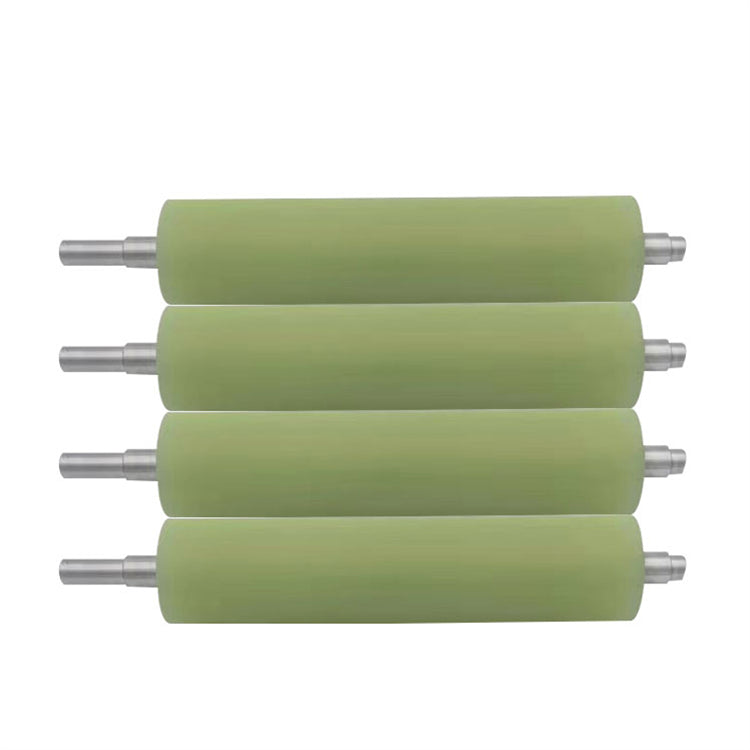

Polyurethane rubber roller

With high strength compression wear resistance, oil resistance, solvent resistance, corrosion resistance, hardness can be customized according to the demand, often used in papermaking wood industry processing, transmission machinery, plastic processing equipment, etc

Silicone rubber roller

High temperature resistance, extreme cold resistance, ozone resistance has good chemical stability, mainly used for processing hot sticky products, such as polyethylene calendering, emboding and film and plant film agent plastic composite, corona treatment and other machinery, suitable for film drenching machine, film industry and clothing bonding machine and other equipment working at high temperature industrial roller machinery, temperature resistance

EPDM rubber roller

It has good oxidation resistance, ozone aging resistance, weather resistance and good electrical insulation performance. It can work in the environment of -65°-140 for a long time In plastic printing machinery, tanning equipment, etc

Liquid Silicone Rubber

It is a kind of advanced synthetic rubber roller, which is condensed by several kinds of rubber materials. With excellent wear resistance, high temperature resistance, acid and alkali resistance, antistatic, ozone resistance, anti-stick, aging resistance, oil resistance and other high quality cots, used in all kinds of machinery and equipment.

Nitrile-butadiene rubber roller

It is produced by low temperature emulsion polymerization, with excellent oil resistance, high wear resistance, good heat resistance and strong adhesion.Used for printing, printing and dyeing, chemical fiber, paper, packaging, plastic processing equipment such as oil and fats and other contact the occasion of the solute

Sticky Rubber Roller

Using imported materials, precision can reach 0.02mm, suitable for electronics, polyester, silk chemical fiber, leather, plastic, paper, printing and other smooth surface.

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements