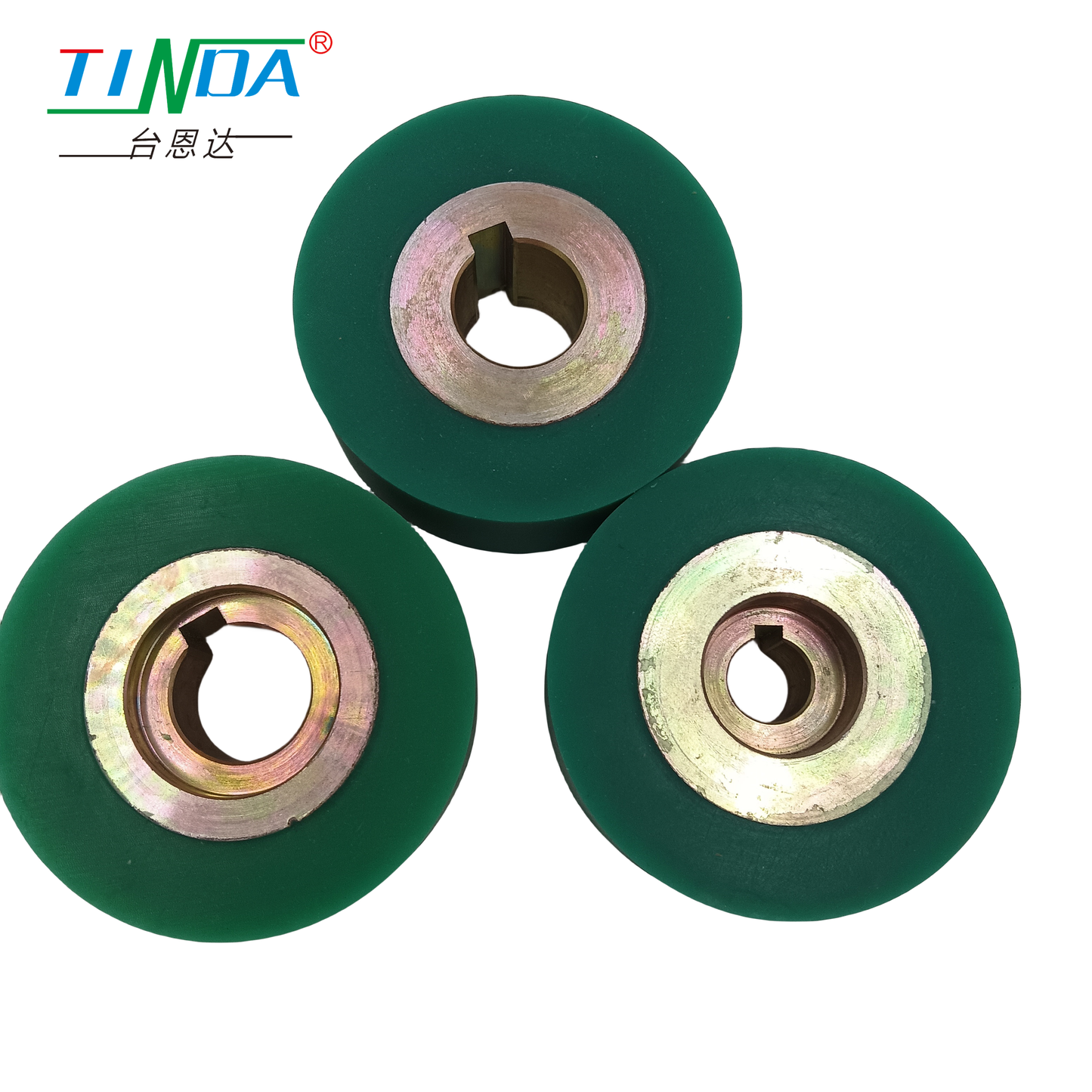

SILICONE WHEELS

Features:

PU Rubber wheel is idea for transferring decorative cylindrical and large flat or curved surfaces.

It has excellent wear resistance, hight emperature resistance, aging resistance,good resilience, and can withstand high pressure and high speed. Glossy appearance, smooth surface, no degumming

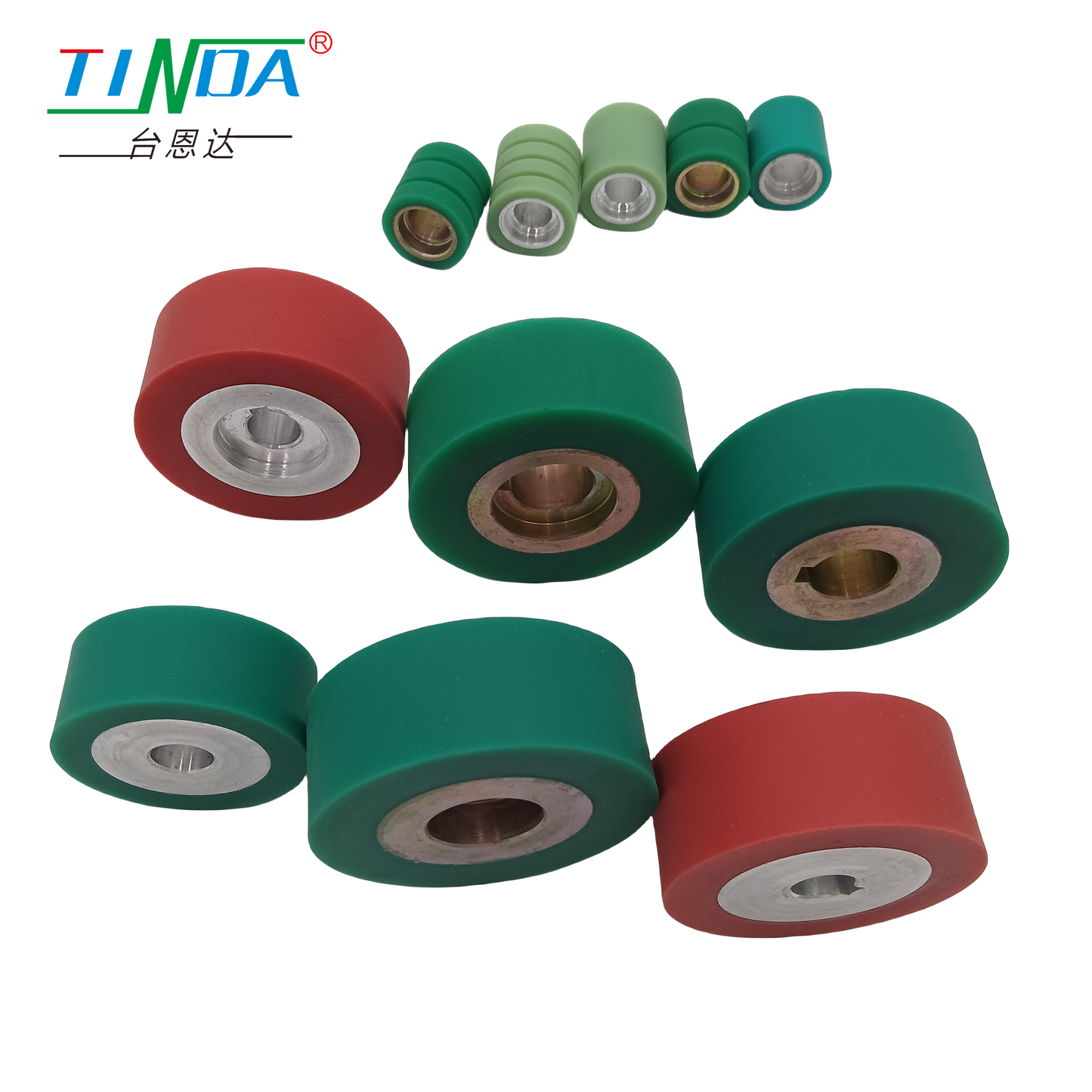

SILICONE RUBBER WHEEL

Features:

√ Materials according to customer demandselection, not degumming

√ One casting molding, high precision

√ Wear resistance, long service life

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements