TINDA GROUP

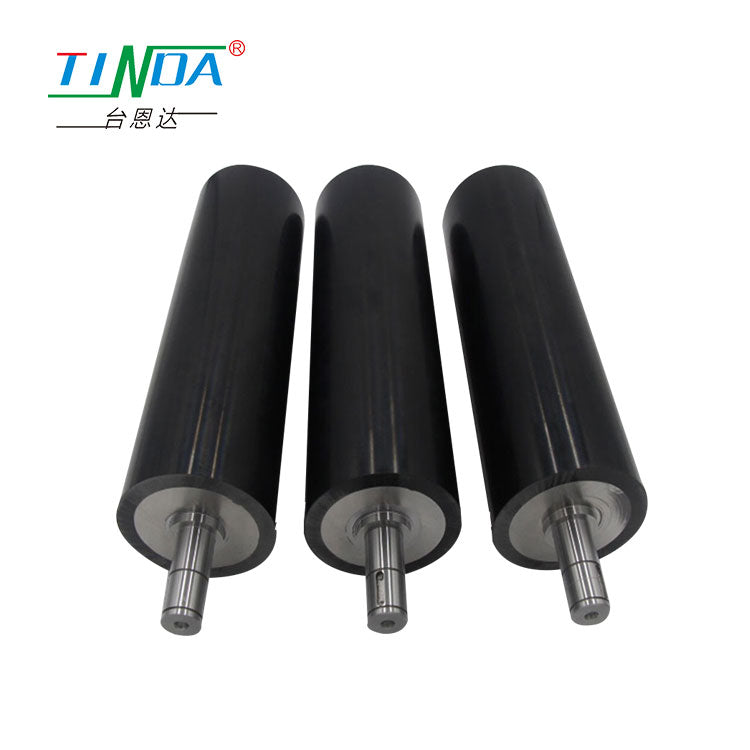

High precision anti-static Automatic rubber roller

High precision anti-static Automatic rubber roller

Couldn't load pickup availability

- Automatic rubber rollers are used in various industrial applications for their efficiency and ease of use.

- They are designed to automatically apply pressure to a substrate without requiring manual adjustment.

- Automatic rubber rollers are commonly used in printing presses, laminating machines, and other manufacturing processes.

- They can be customized in terms of size, hardness, and surface finish to suit different applications.

- Proper maintenance and cleaning is important to ensure consistent and effective performance.

Imported excellent rubber materials are used, and the cots are made of high-tech anti-stick technology, which has high precision anti-static, high strength, wear resistance and long service life

Rubber selection with NBR butyl rubber, silica gel, epD, neoprene rubber, PU polyurethane rubber, temperature resistance, pressure resistance, high temperature resistance, anti-stick, antistatic, widely used in leather, glass, plastic, packaging, ceramics, stainless steel plate, aluminum plate, carton, artificial SLATE, circuit board, woodworking, furniture, textile printing and other industries on the laminating film, veneer fitting, laminating machine, Welcome to call to map custom

Multiple specifications Multiple options

Can choose the applicable design with the actual situation, can pressCustomer requirements processing customized

| Papermaking roller | Printing and dyeing roller | Printing roller | |||

|---|---|---|---|---|---|

| Name | Hardness | Name | Hardness | Name | Hardness |

| Press roller | 80°-90° | Press roller | 92°-97° | High speed rotary press roller | 20°-25° |

| Water extrusion roller | 75°-85° | Mercerized roller | 80°-85° | High-speed platform ink roller | 80°-85° |

| Dryer roller | 85°-95° | Mercerizing flat washroller | 80°-85° | General platform ink rolle | 100° |

| copper mesh roller | 35°80° | Flat Wash upper roller | 100° | Offset press grinding roller | 80° |

| Blanket dispensing roller | 95°-100° | Flat Wash lower roll | 80° | General printing ink roller | 85°-90° |

| Case roller | 95°-100° | Rope washing machine roller | 85°-90° | Strong solvent glazing roller | 85° |

| Breast roller | 70°-80° | Tie dyeing roller | 85° | Strong solvent glazing roller | 60°-70° |

| Wool cloth guide roller | 95°-100° | Hollow bending roller | 60°70° | lron printing roller | 95°-100° |

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements