Our steel rolls are used in many industries, mainly Including precision coating, casting, hot melt coating and Other process areas. They are optical films, lithium batteries Coating, lithium battery separator, release paper/film, emery Cloth/abrasive belts, special tapes, textiles, liquid packaging,rolls Paint and other industries

Customized method: Make according to drawings, send samples to make, make according to size.

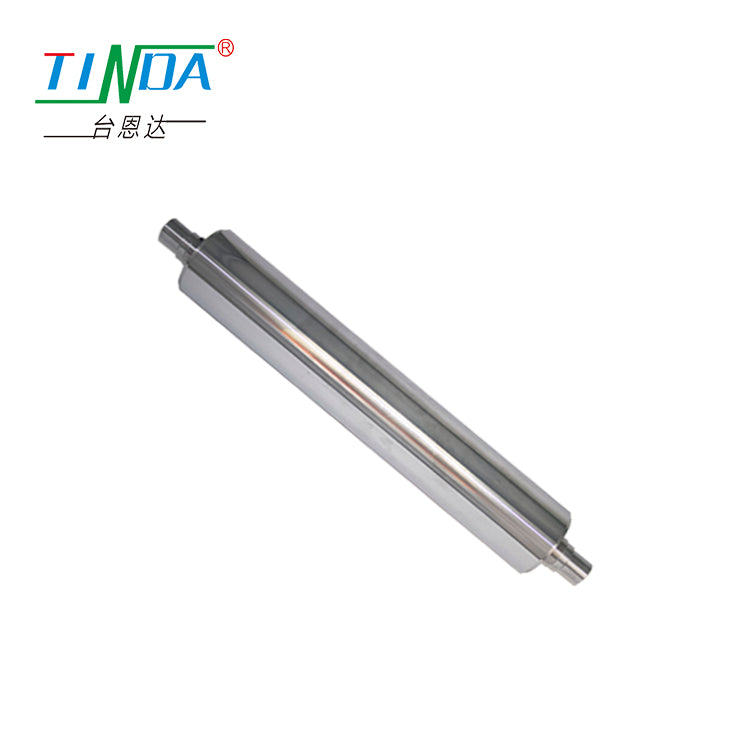

Steel step

Features: It is cheap and after quenching and tempering (or normalizing), it can obtain better cutting performance, and can obtain higher strength and toughness and other comprehensive mechanical properties.The surface hardness after quenching can reach 45-52HRC

Disadvantages: easy to rust (need to do anti-rust treatment

Material: 45 steel

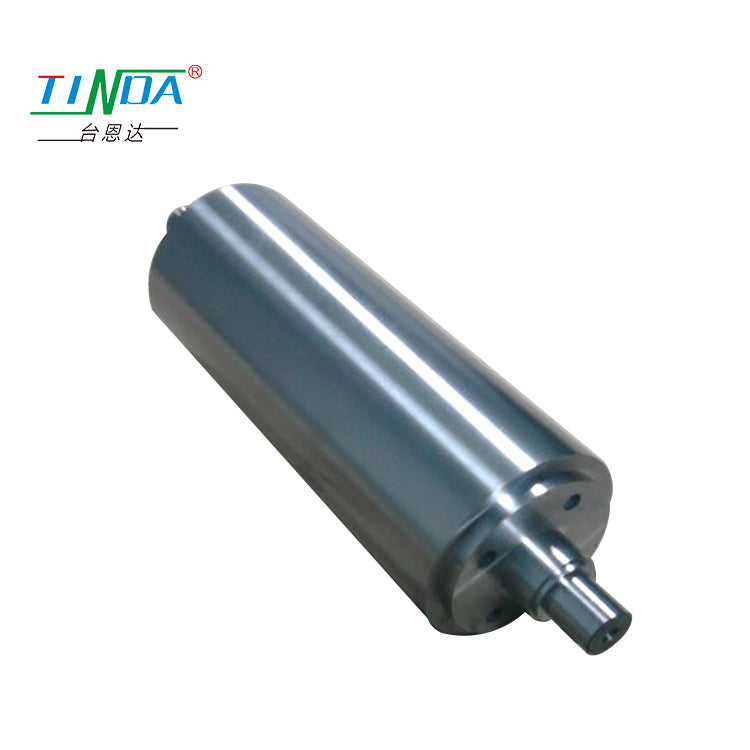

Stainless steel roller

Features: Has good corrosion resistance, wearresistance, high hardness, long service life,high finish, not easy to rust, etc.

Material:316/304 stainless steel

Customized method

Make according to drawings, send samples tomake, make according to size

Aluminum roller

Features: The aluminum alloy guide roller has the characteristics of high strength,low resistance, light weight, smooth transportation, no rust,and good wear resistance and corrosion resistance.

Surface treatment

Can be sandblasted, textured, Teflon, other hardening treatment HV700 Make it have higher abrasion resistance,hardness and durability

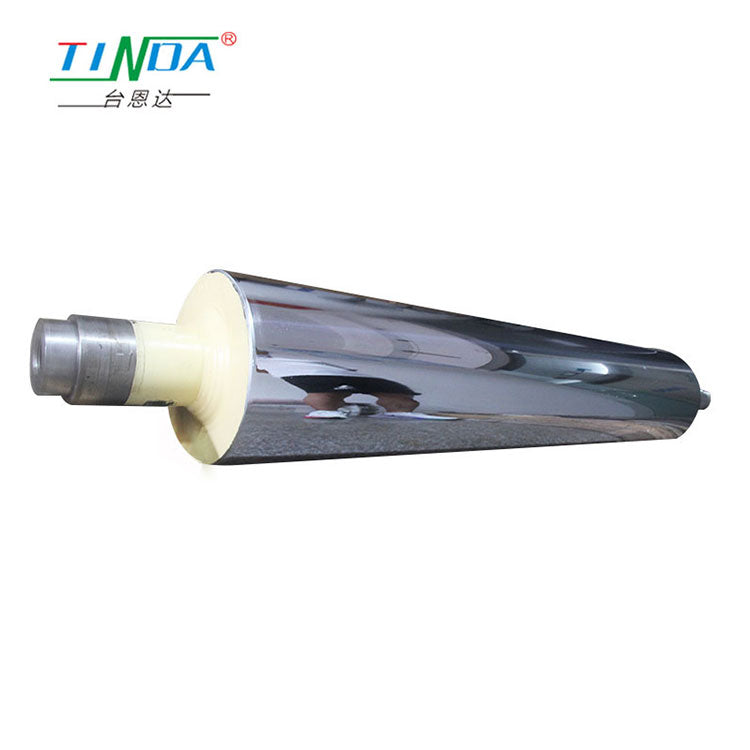

Mirror steel roller

Features: .Our mirror steel rods have super high finish,can reach optical grade, super high hardness,wear resistance and smooth surface

Material:316/304 stainless steel

Teflon steel roller

Features: a variety of colors, have high-strength anti-sticking properties, strong anti-corrosion ability,imported materials,and long service life

Pneumatic shaft roller

Features: Excellent flatulence function, strong sealing, no air leakage, strong abrasion resistance,long service life

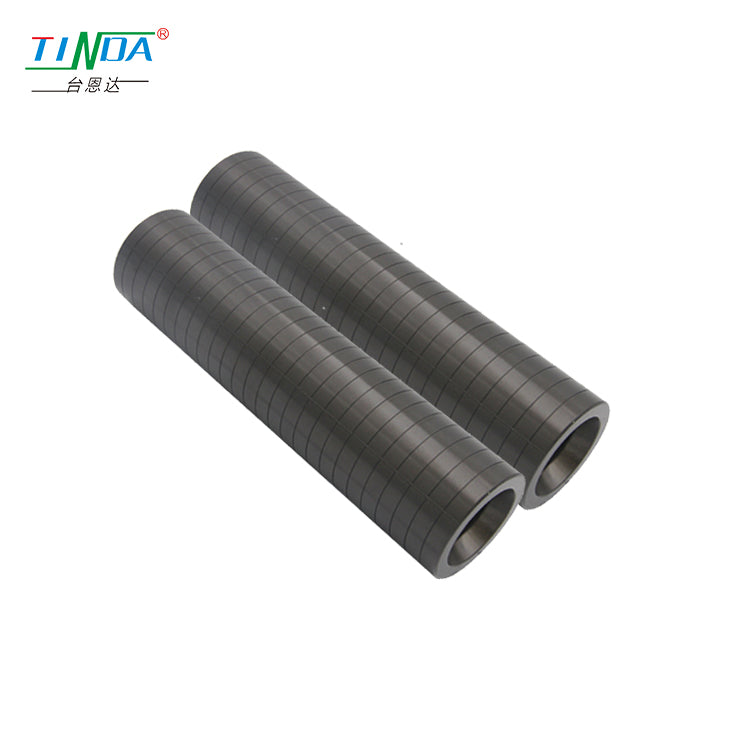

Ceramic Anilox Roller

Features: ink printing, uniform ink transfer,fast ink transfer

Application industry: Printing, printing and dyeing

Mask machine embossing roller

Customized method

Make according to drawings, send samples tomake, make according to size

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements