Good electrical insulation

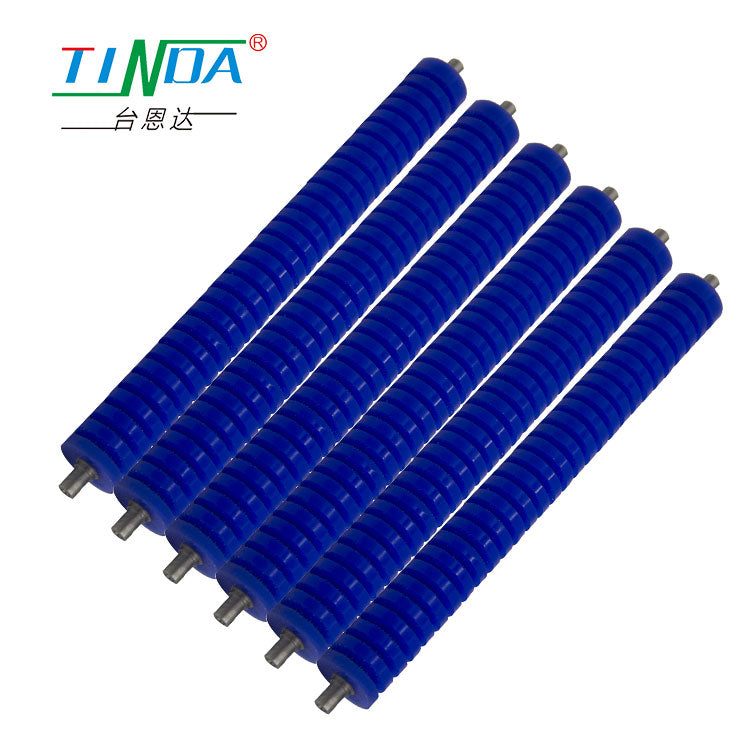

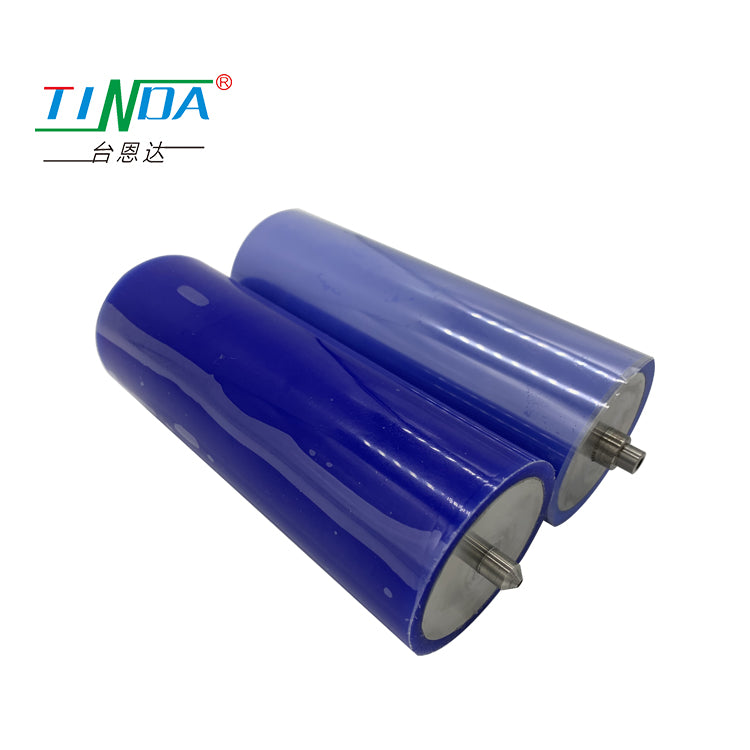

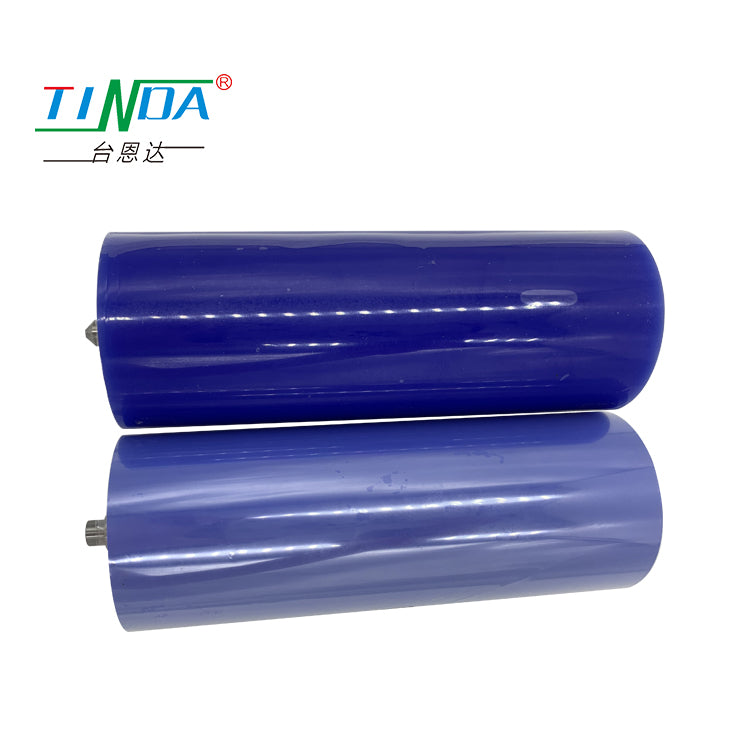

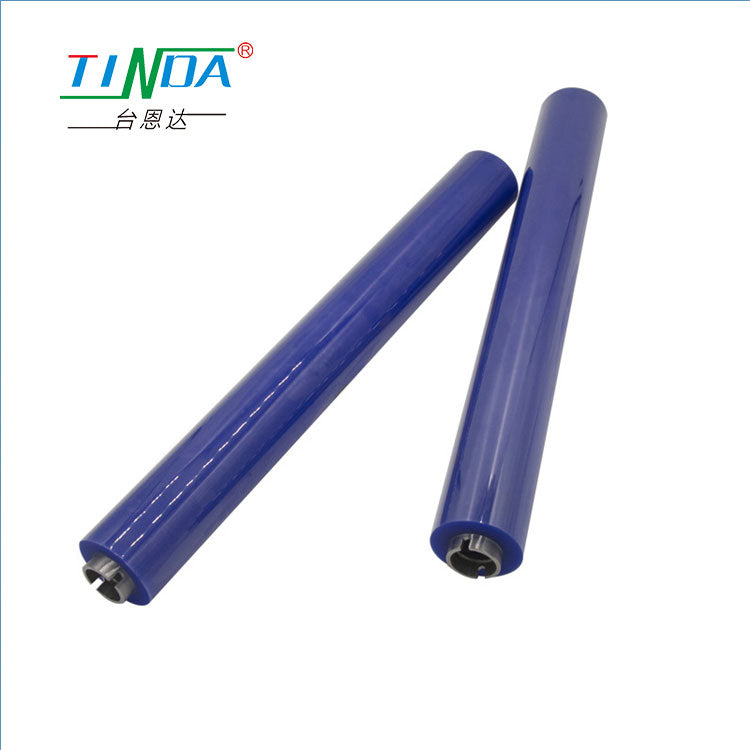

1. Material: silica gel, butyl

2. Hardness: conventional 30-60 degrees

3. Color: blue, white

4. Viscosity: non-viscous,low-viscositymedium-viscosity,high-viscosity,extra-highviscosity

5. Packaging: one in a bag, one in a box

6. How to use: Recycle with sticky paper

7. Scope of use: dust cleaning

8. Size: 4inches/6 inches/8 inches/10inches/12 inches/14 inches and largerspecifications

9. Product features: stable raw materialdurable, non-aging,non-debris, anti-staticmoisture-proof,moisture-proof,friction-resistant,insect-proof,rust-free, andpollution-free.lt is comfortable to use androtates smoothly

STICKY RUBBER ROLLER FOR MACHINE

Adhesive rubber rollers used in industrial machinery and automation equipment have a sticky surface

CLEANING METHOD (THERE ARE 3 WAYS)

1. Alcohol wipes the sticky rubber roller

2. It can be cleaned with sticky paper roll

3.It can be used in conjunction with dustcollecting wheel, low viscosity rubber rollerand high viscosity rubber roller, highviscosity can remove low viscosity dust

STICKY PAPER ROLL

Clean the rubber roller

Step 1 : The shaft head is processed by internal welding and our iron core is processed by first-class steel to achieve high precision and high quality.

Step 2 : In the production process of each rubber roller.we will conduct 3 dynamic balance tests,Will ensure the use effect.Generally, if it can be displayed within 10g on a dynamic balance device, it is called dynamic balance. But we can do less than 2 grams

Step3: Our rubber material is imported from Japan,United States, and then mix the rubber materials According to customer requirements. We will record Every time we mix rubber materials, we need a formula Small pieces are cured and tested for 24 hours Hardness, flexibility, resilience, etc., only need to meet Customer request

Step4: We have more than 10 running-in machines, whichcan quickly and effectively control each size of therubber roller to meet the customer's drawing requirements